Rutland Cranes was appointed to deliver a full contract lift solution for the replacement of conveyor lines inside a live warehouse facility operated by a global brand. Working closely with our long-standing mechanical engineering partner, our goal was to complete the project safely and efficiently with minimal disruption to site operations.

The Challenge

The site posed several operational constraints:

- Live facility with ongoing warehouse operations

- Low headroom constraints due to overhead cable trays

- Tight timeframe: operation must be completed in 4 days

- Requirement to avoid noise and diesel emissions within a clean indoor environment

Our Solution

Following a full site survey and pre-lift planning phase, we selected the Maeda MC-405 spider crane for its great lifting capabilities at long reach, precision control, and zero-emissions electric motor – ideal for indoor lifting.

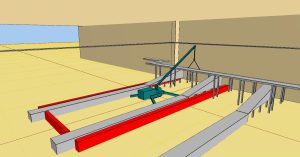

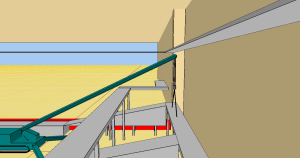

Our team worked closely with warehouse management to create a clear access strategy and coordinated lift schedule. The crane and load path were designed to operate under the restricted ceiling space while ensuring the conveyor could be installed without risk to equipment or site personnel.

The project was backed by our Lift Plan, RAMS, and 3D lift model, providing full transparency and assurance throughout.

The Outcome

- Lift completed in 3 days instead of 4, thanks to meticulous planning and crew efficiency

- Limited disruption to warehouse operations

- Accelerated restart of the production line, saving the client time and cost

- Client praised the seamless delivery and professionalism of the Rutland Cranes team