This project demonstrates the advantages of spider cranes for confined-access lifting. Rutland Cranes was appointed to carry out a full contract lift at a manufacturing site in Royston, assisting a specialist steel fabrication contractor with the safe installation of new pipe bridge structures.

The Challenge

The site posed several operational constraints:

- Tight access for crane setup, particularly within live internal access routes

- Need to operate within a defined schedule to minimize disruption to factory operations

- Strict safety protocols due to personnel and machinery movement in the work zone

Our Solution

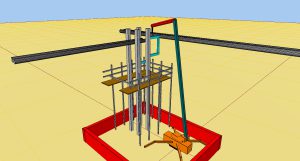

Following an on-site survey and collaboration with the client, we selected the Jekko SPX532 spider crane for its compact footprint and powerful lifting range.

We took full ownership of site coordination, engaging directly with the main contractor to manage timing, access, and safety. Lift operations were carefully scheduled and aligned with factory shift patterns to avoid downtime and eliminate risk to site personnel or the public.

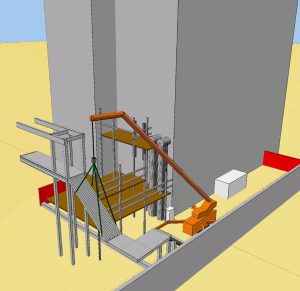

All works were carried out under our Lift Plan and RAMS, supported by a 3D lift simulation for visual planning and assurance.

The Outcome

- Project split across three scheduled site visits

- Zero disruption to factory production

- All lifts completed safely, on time, and fully compliant

- Delivered peace of mind to the client through full contract lift service